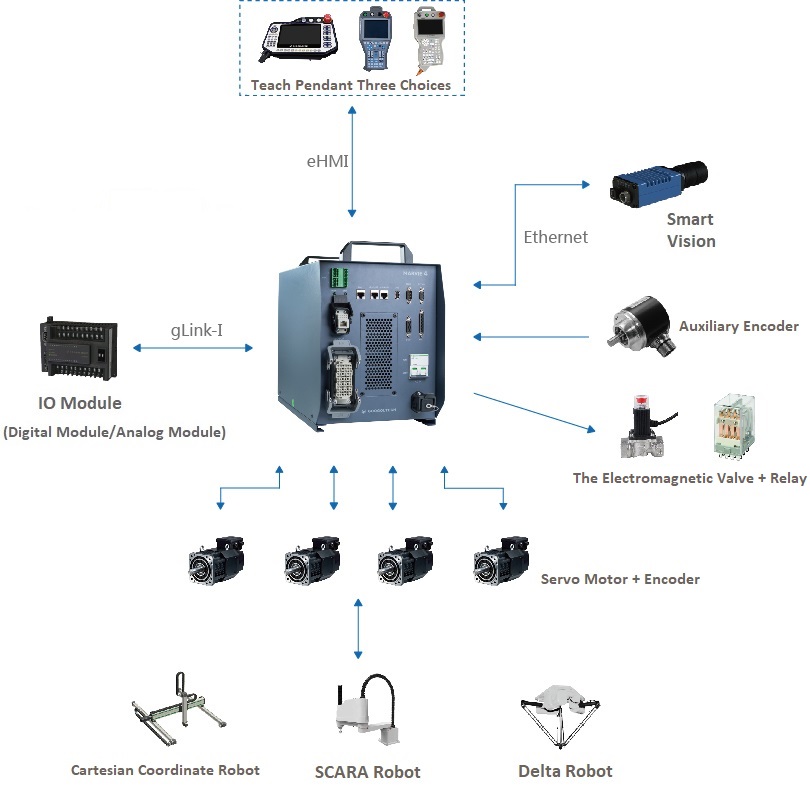

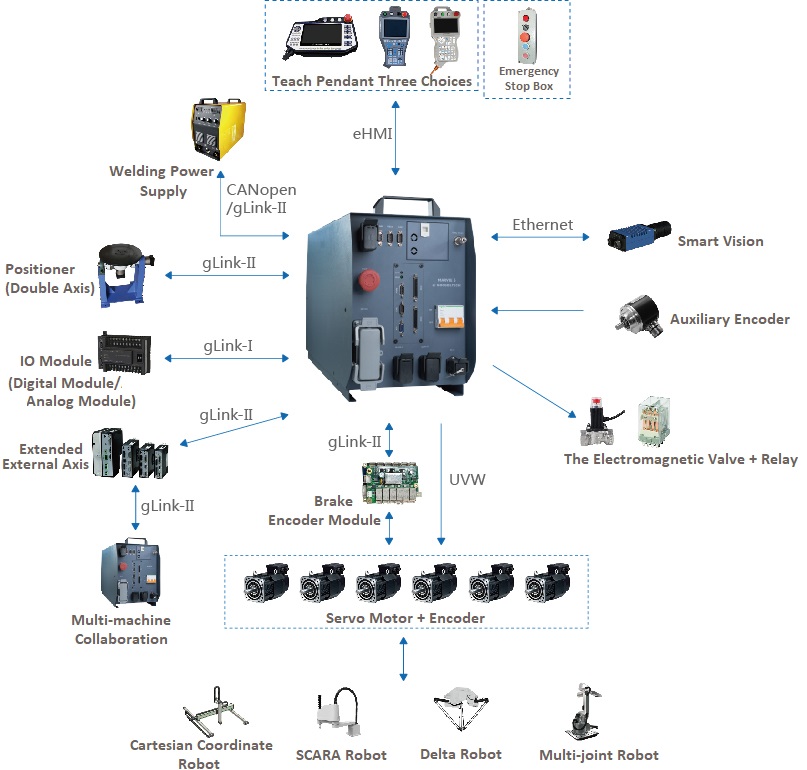

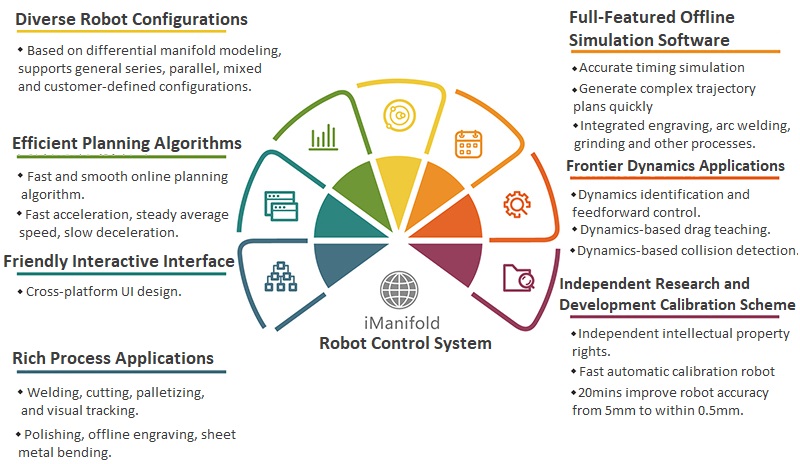

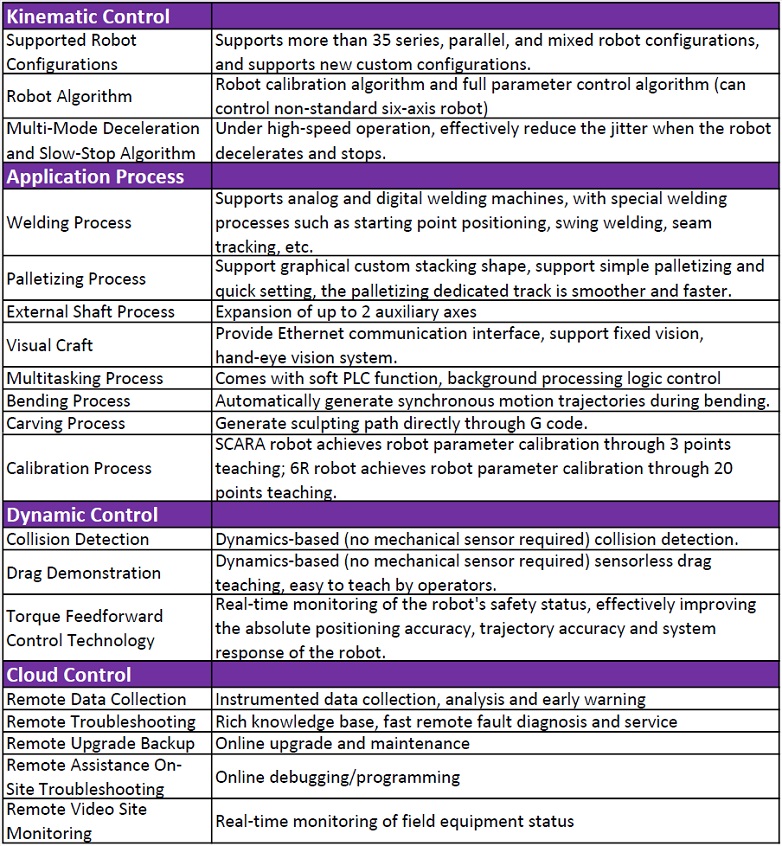

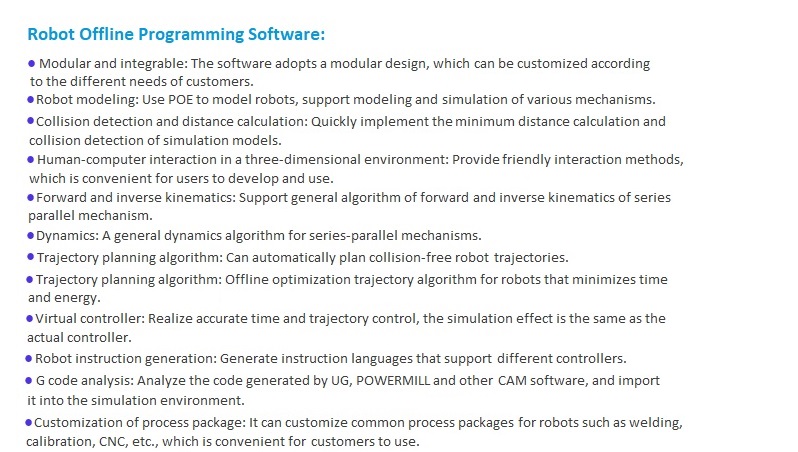

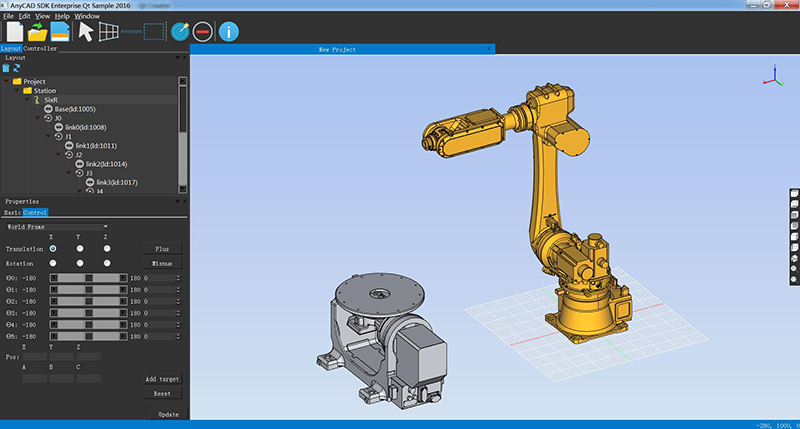

Googoltech's industrial robot control system development platform consists of open, reconfigurable hardware platform and software platform. The development platform is based on WINCE operation system to meet the real-time, security and stability requirements of robot applications. Aiming at the robot manufacturer with development ability, the industrial customer with industry application demand and the Research Institute of the university, the platform adopts the system architecture which can be redeveloped, and provides the solution for customizing the process and algorithm for the customer.

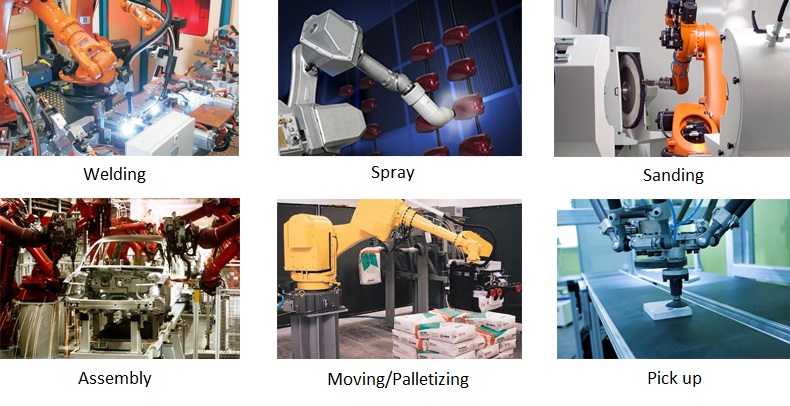

Robot control system development platform provides arc welding, spot welding, cutting, spraying, handling, assembly, processing, palletizing, follow-up, CNC carving and other processes, widely used in automotive, food, packaging, laser and other industries.

● Support teaching, playback, remote control mode.

● Support offline editing of teaching documents.

● Support multi workspace monitoring (workspace, obstacle space, space restriction).

● It has the function of forward and backward teaching and inspection, robot numerical control and simulation running function.

● Joint space PTP instruction, Cartesian space PTP instruction, Cartesian space straight line, circular arc CP command

● Supporting robots of different configurations, supporting more than 35 industrial robots with 4-6 axis standard and non-standard structures

● Adjustable robot dynamics parameters.

● The servo drive system of common mainstream brands can be configured.

● Support customer defined ontology configuration and two custom process modules development.

● Support two external axis control to achieve 8 axis linkage.

● Support robot numerical control engraving process.

● Support no sensor dragging instruction function (support robot dynamics parameter calibration).

● Support robot calibration algorithm module (special inspection equipment support).