Googol Technology Empowers Semiconductor Equipment to Improve Quality and Efficiency

2023-10-08

mktadmin

Googol Technology has been deeply involved in the field of industrial automation for more than 20 years, focusing on the key techniques of semiconductor processes, providing customized motion control solutions with high speed, high precision, stability and reliability for semiconductor equipment, comprehensively improving the quality and efficiency of semiconductor equipment, and realizing lean manufacturing in the semiconductor industry.

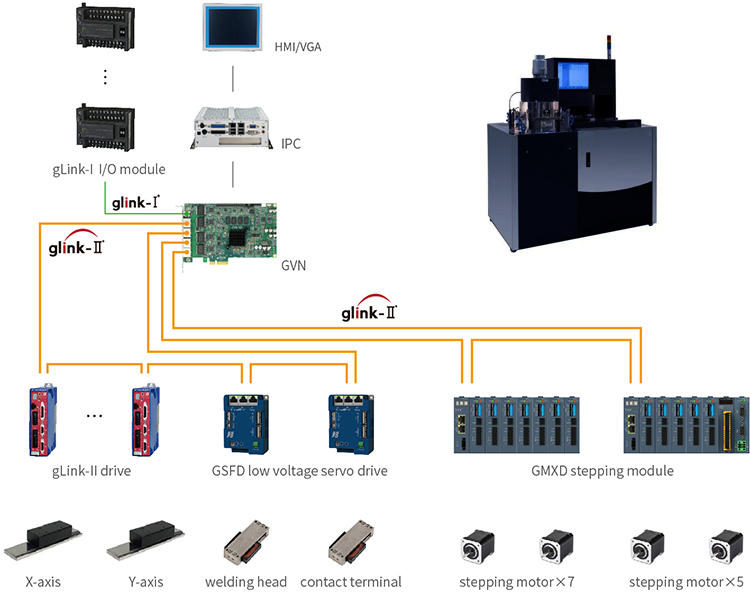

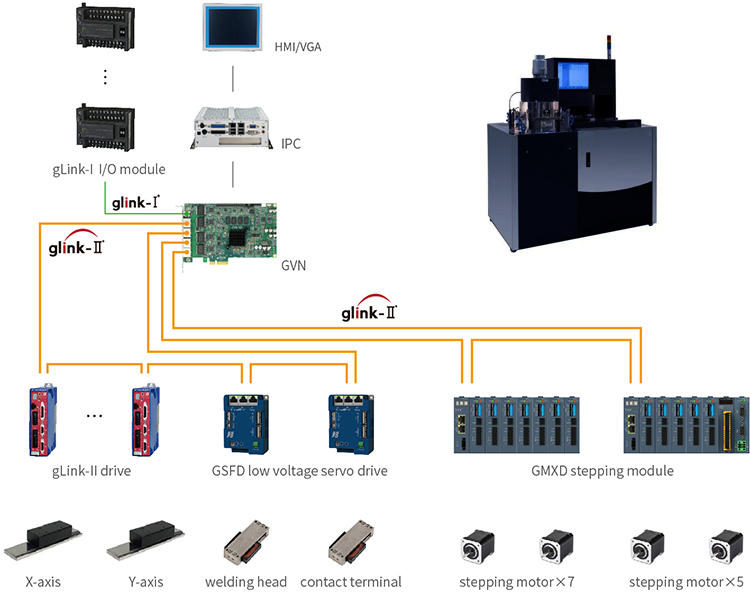

High-Speed Wire Bonder

● Provide high speed gLink-II and general-purposed gLink-II gigabit net ring protocol to satisfy various technique requirements of devices

● communication cycle up to 50us, supporting high-performance closed-loop, force-position, gantry, force-position, gantry, contour error control algorithm

● gLink-II gigabit net ring communication protocol ensures high speed real-time response and big data transmission of the system, and the dual-redundant data link ensures communication data security and reliability

● Support on-site application reconfiguration and tuning due to the diversity of end-customer products and high degree equipment non-standardization

● LED, MiniLED, IGBT, integrated circuits

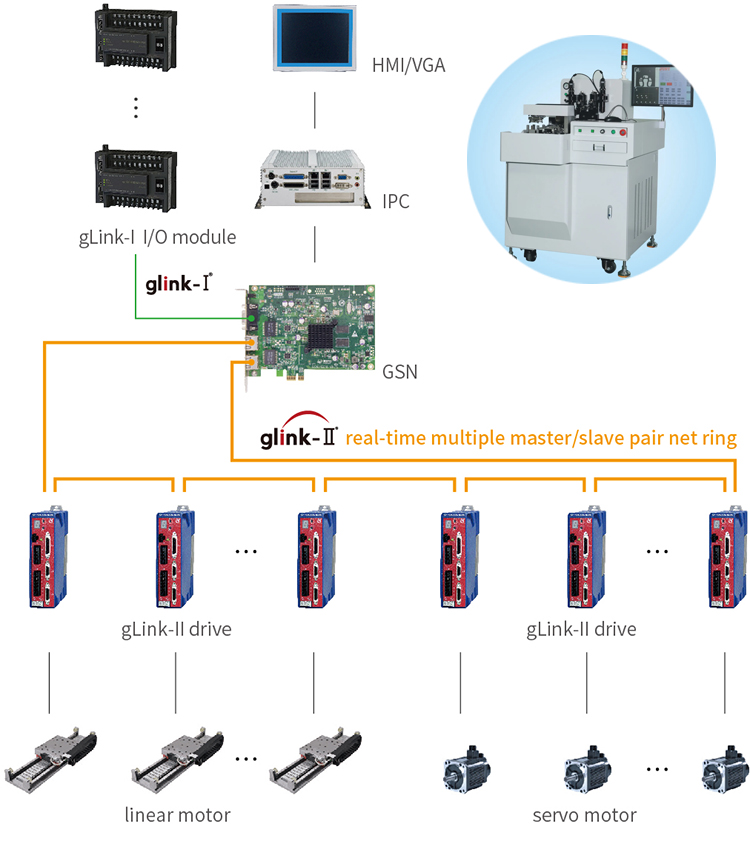

High-Speed Die Bonder

● GSN+GSHD motion control solution realizes multi-axis high speed and high precision motion control

● GSHD’s torque control function controls the pressing force of chip suction and release to prevent chip damage and deformation

● Flexible expansion to achieve multi-station collaboration and improve production efficiency

● Compact system structure, convenient wiring, safe and reliable

● gLink-II gigabit net ring communication protocol ensures high speed real-time response and big data transmission of the system, and the dual-redundant data link ensures communication data security and reliability

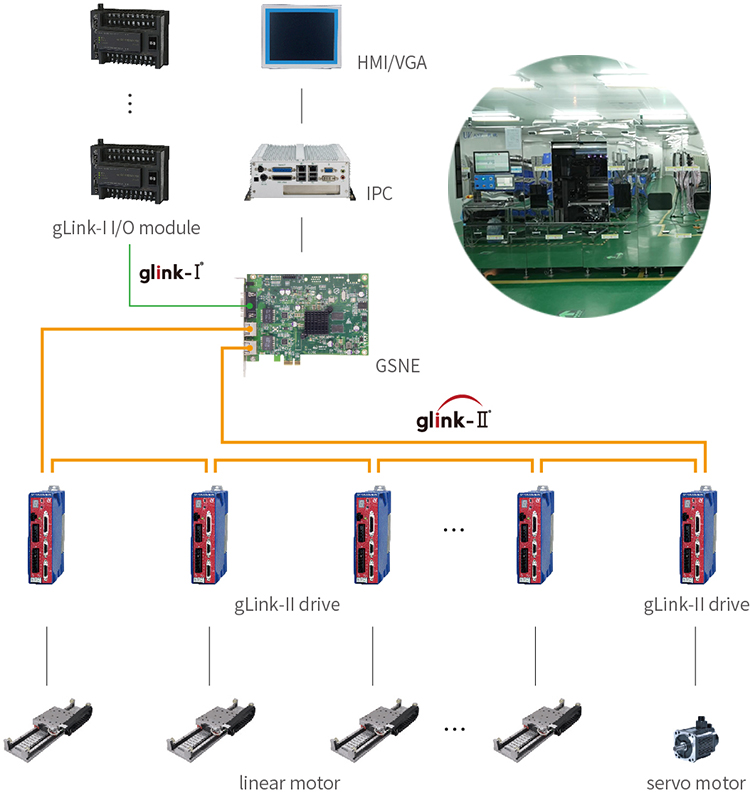

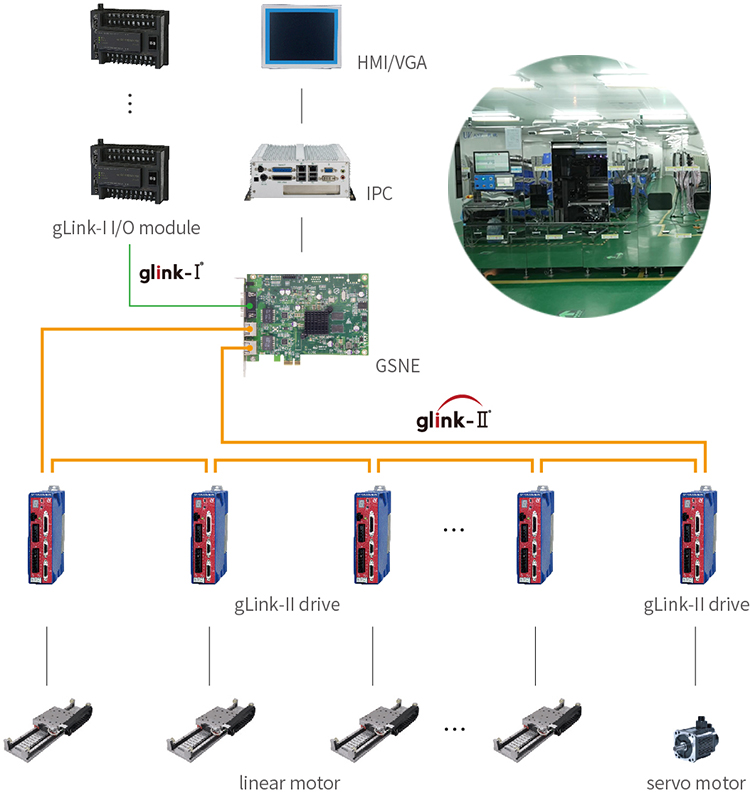

LDI Exposure Machine

● High efficiency: The GSNE+GSHD motion control solution has a control cycle of 250us, improving equipment efficiency by 25% compared to foreign systems

● High speed and high precision: gLink-II gigabit net ring communication protocol, ensuring high speed real-time response and big data transmission

● Cost-effectiveness: Stable performance and significant cost advantages

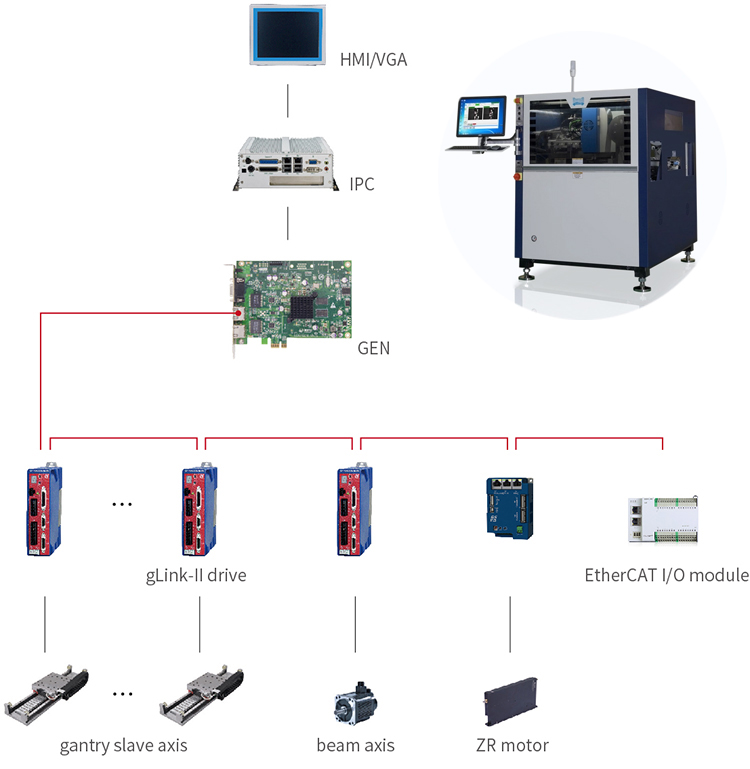

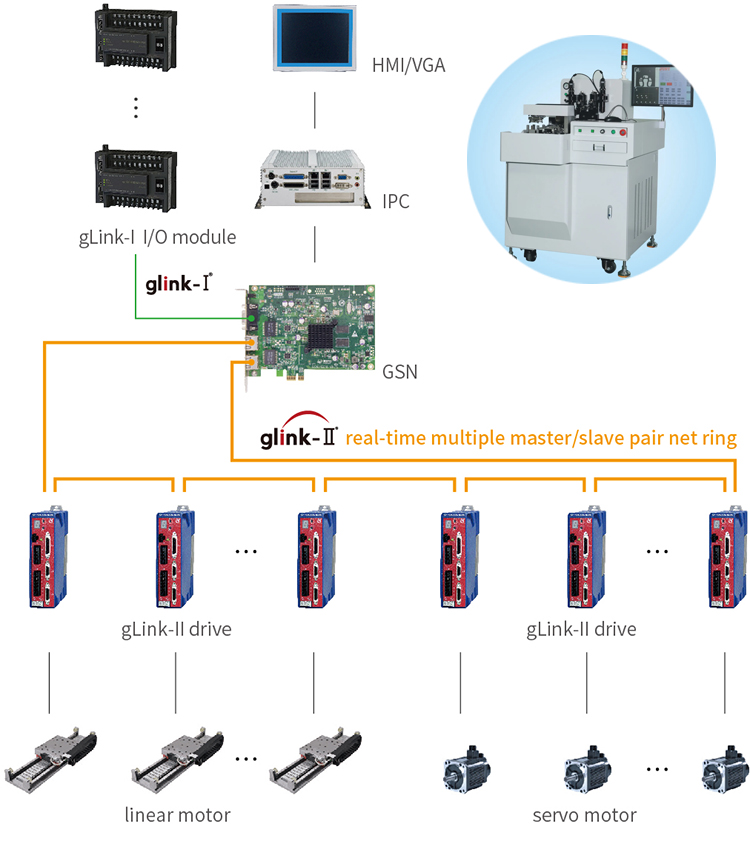

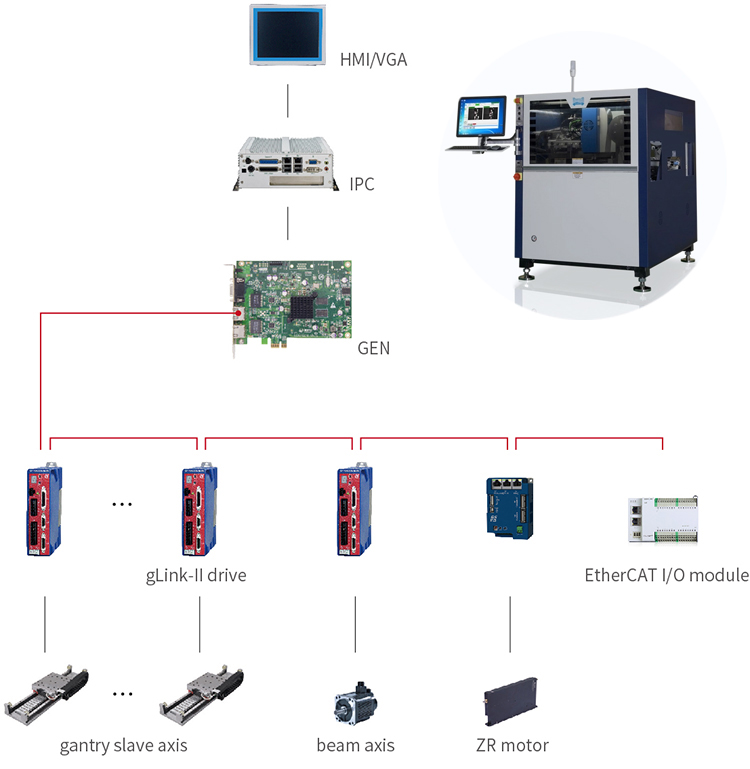

High-Speed Mounting Machine

● Soft landing function, sensorless force control

● No programming required, triggered by I/O automatically

● Pressure ranges from 10g-2000g, with an accuracy of ±1g

● Press fitting cycle less than 150ms

● Supports open-loop force control/closed-loop force control

● IGBT, IPM, rectifier, fast recovery, TO, and thyristor components

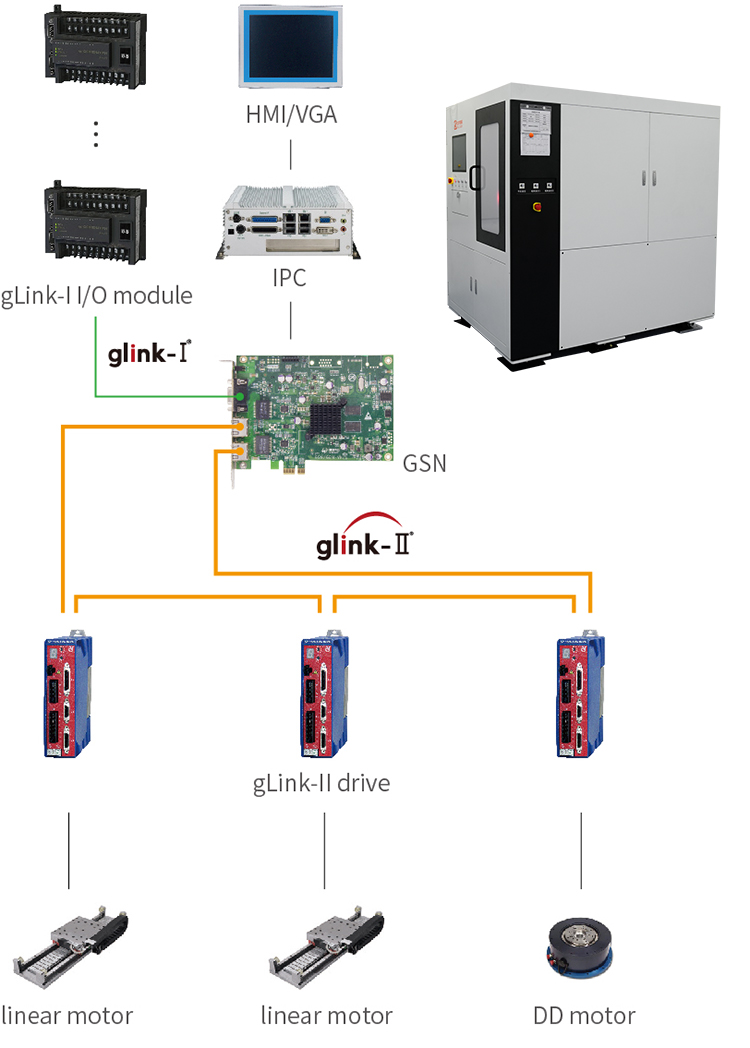

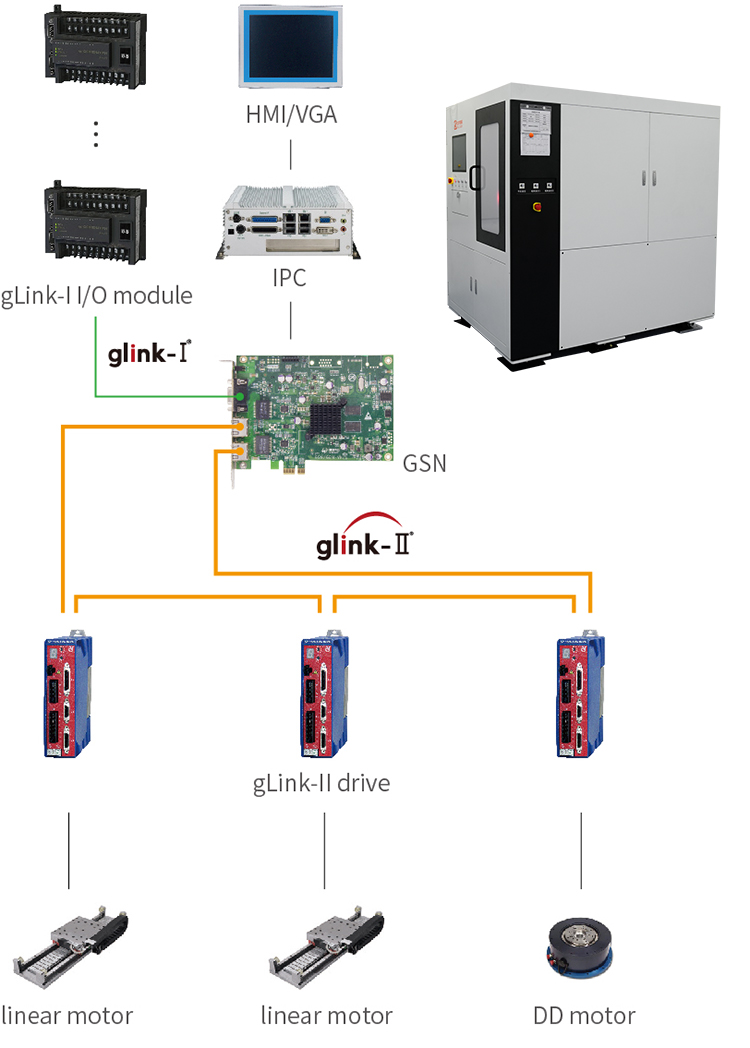

Wafer Dicing Machine

● The GSN+GSHD motion control solution based on the gLink-II gigabit communication protocol meets the high speed and high precision requirements of equipment techniques

● X-axis maximum speed: 800mm/s, acceleration: 2-4G, repeat positioning accuracy: 0.5um, positioning accuracy: 1um, X and Y axes jitter: ±3 counts, R-axis jitter: ±5 counts, when there is no movements in X and Y axes, R-axis jitter: ±0.5um

● MiniLED, photovoltaic

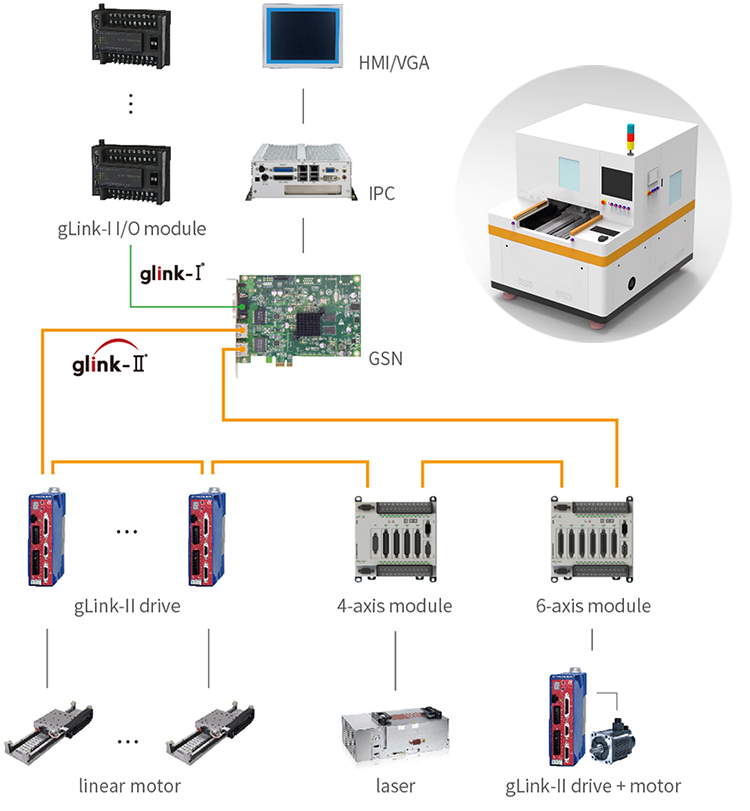

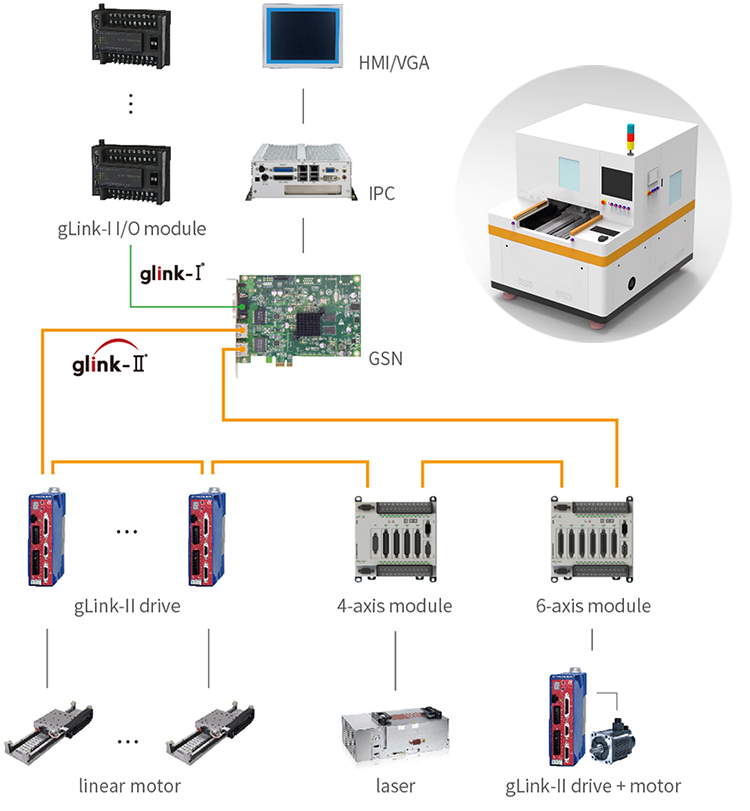

High Precision Laser Cutting

● The gLink-II bus enables fully interconnection of motion control, laser control, servo drive and motor to realize high speed real-time control

● PSO (equidistant output) function: outputs laser control signals equidistantly along the two-dimensional trajectory, accurate and reliable, maximum frequency 4MHz

● Adaptive algorithm: significantly improves contour accuracy processing, with contour error within 5um

● Smooth velocity planning: features velocity look ahead, S-curve motion, and other functions

● High performance drive: paired with the GSHD series servo drive with high speed current loop, velocity loop and position loop, providing extremely high control precision and response velocity

Wafer Transfer Robot

● Provides the fastest 1ms robot kinematic calculation and high-order S-curve velocity planning for ultra-flexible motion control of wafer transfer

● Advanced vibration suppression control algorithm to avoid vibration during wafer transfer and achieve fast and accurate positioning

● Provides high speed gLink-II gigabit net ring communication protocol for high speed data interconnection between devices

● Offers high speed wafer edge detection for high speed and high precision wafer position detection and real-time compensation

● Open software architecture, supports independent development of motion control and technique functions

● High reliability, integrated intelligent drive, fanless fully enclosed design, suitable for clean room applications