Application Stories - GSN Series Motion Control Card

2020-08-31

mktadmin

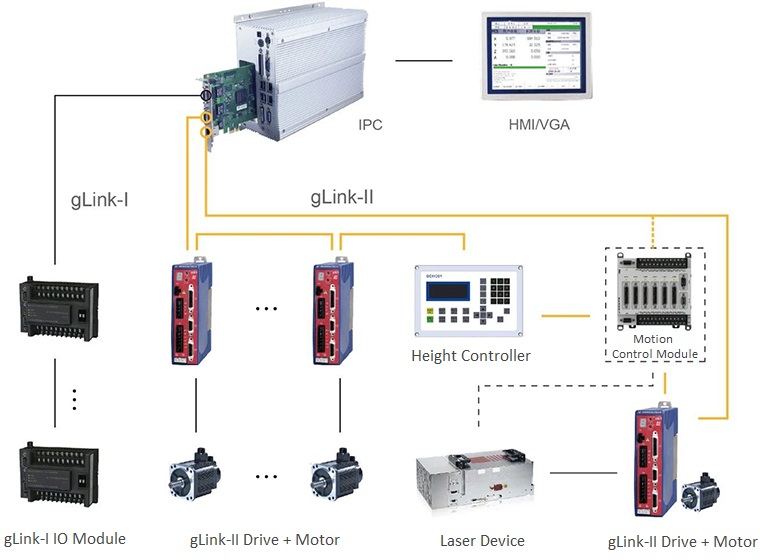

GSN series motion control card is a

network-type, modular plug-in card motion controller. The product is based on

Googoltech's gLink-II bus and has a built-in high-performance motion control

algorithm that can complete complex path planning and control. The application

of GSN series motion control card in laser cutting, five-axis dispensing and

gantry control highlights its high cost performance and high reliability.

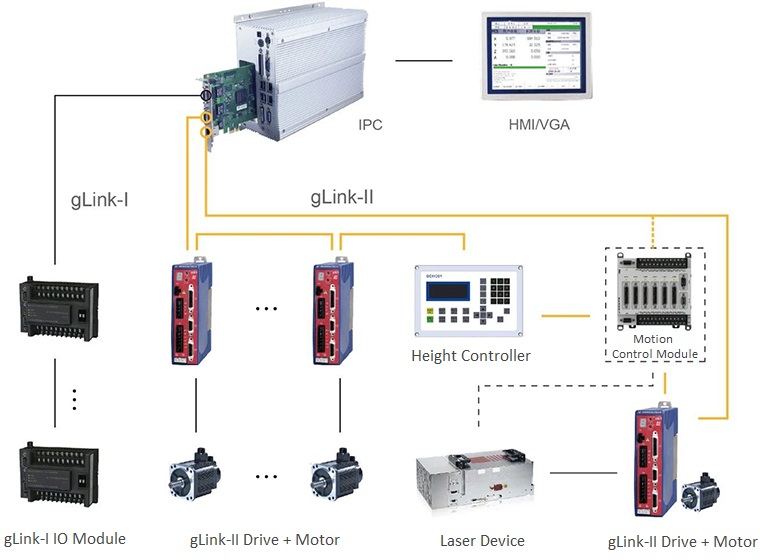

A. Laser

Precision Cutting

As glass and ceramics are widely used in

intelligent products such as smartphones, tablet computers and wearable

devices, their fragile characteristics have become a major challenge for laser

cutting equipment. GSN series motion control card contains PSO algorithm and

adaptive algorithm. Through the gLink-II bus, motion control, laser control,

high-performance GSHD series servo drives and motors are fully interconnected, helping

customers to perform processing on thin and brittle non-metallic materials such

as glass and ceramics. The laser dot pitch is about 1um, and the contour error

is within 5um.

Features:

● PSO (Position Synchronized Output): The laser control signal is output at equal intervals along the two-dimensional trajectory direction, which is accurate and reliable, with the highest frequency of 4MHz.

● Adaptive Algorithm: Draw a 3mm positive and negative circle, after using an adaptive algorithm, the machining contour accuracy is significantly improved.

● Smooth Speed Planning: With speed forward, S-curve movement and other functions.

● High-performance Drive: GSHD series servo drive with high-speed current loop, speed loop and position loop, the system has extremely high control accuracy and response speed.

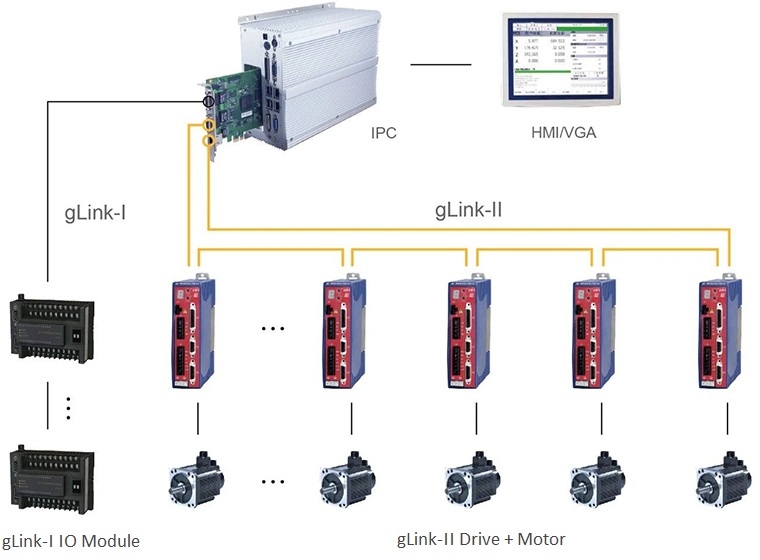

● Ring Network Interconnection: Googoltech's gLink-II bus interconnects motion control, laser control, servo drives and motors to achieve high-speed real-time control.

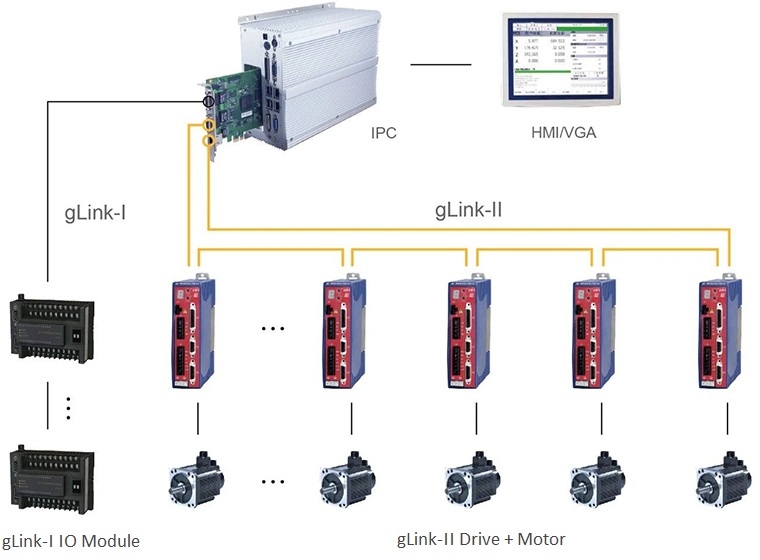

B. 5-Axis Dispensing Machine

Dispensing has become an indispensable link

in the production and processing of smart phones, tablets and other wearable

devices. For simple point, straight line, arc, ellipse, inner wall, outer wall

and vertical surface dispensing, ordinary three-axis or four-axis dispensing

machine can be competent. Googoltech's glink-II bus and GSN motion control card

support linear, arc and spiral interpolation, which are widely used for precise

dispensing of circular, irregular and curved products. When the workpiece or

the dispensing head with variable and irregular dispense trajectory is tilted

and rotated freely on the 3D surface, it can ensure uniform dispensing and

uniform thickness of glue path.

Features:

● Five-Axis RTCP Function:

Various interpolation methods can realize arbitrary spatial motion trajectory.

● PSO (Position

Synchronized Output): Output control signals at equal intervals along the

dispensing track direction to ensure the uniformity of glue application.

● Forward-Looking Pretreatment

Function: The dispensing speed is smooth and uniform to ensure the consistency

of the thickness of the glue path and improve the glue corner accumulation.

● High Precision and High

Efficiency: The work piece can be clamped at one time to realize the dispensing

operation of five surfaces, so as to improve the dispensing accuracy and

efficiency.

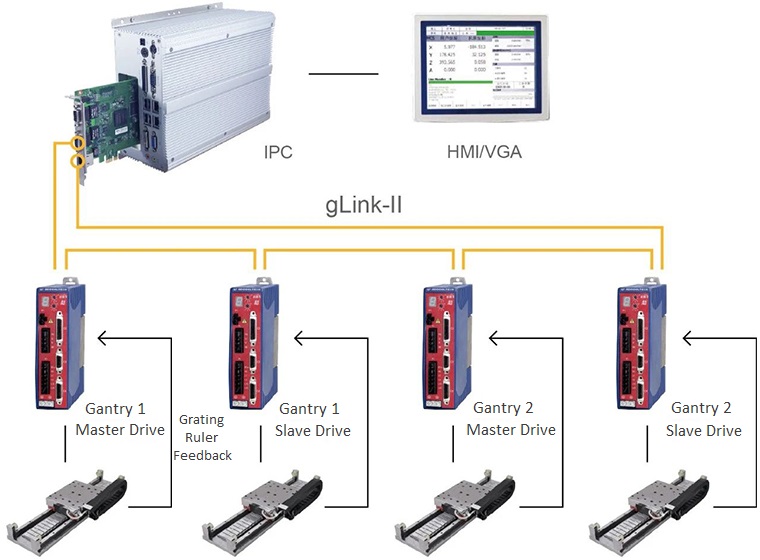

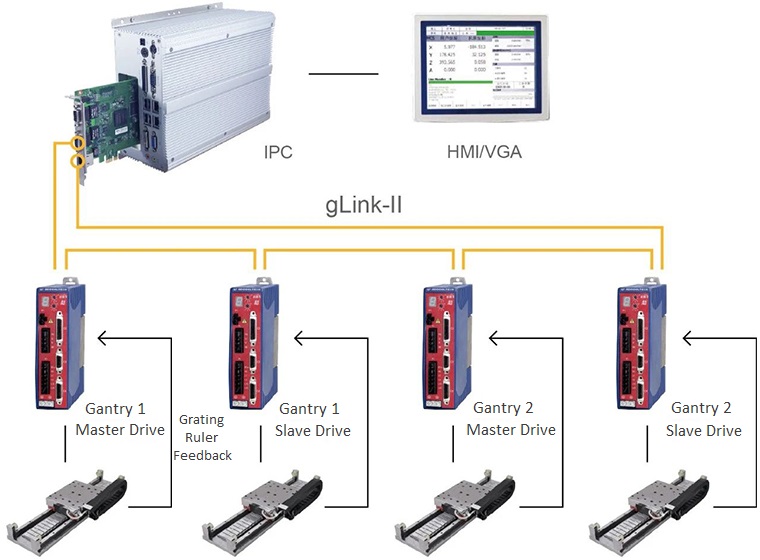

C. Smarter Gantry Control

The gantry structure is widely used in

high-end manufacturing equipment because of its large stroke, wide working area,

high torque and high-power processing. The focus of gantry control is to

control the synchronous movement of the two gantry axes. If there is a big

difference in the movement between the two axes, it will cause damage to the

mechanism. GSN series motion control card has a unique cross-decoupling

algorithm, which ensures absolute synchronization in the operation of the

gantry system and improves the control performance of the system. Multiple

compensation algorithms make the system more stable when the gantry axis and

orthogonal axis are running at the same time. Help customer equipment to achieve

synchronization error accuracy within 1 wire, repeat positioning accuracy

within 5um.

Features:

● Gantry Control Algorithm:

Ensure that the master and slave axes follow synchronously.

● Compensation Algorithm:

Two-dimensional plane error compensation and two-axis mechanical torque

compensation, reduce structural deformation and system power consumption, and

improve the life of the drive.

● Cross Decoupling Algorithm:

Improve the control performance of the system.

● Effectively suppress

low-frequency mechanical resonance.

● Various Zero Return Methods:

Achieve high precision zero return.

● High Cost Performance: Can

control multiple gantry systems at the same time.