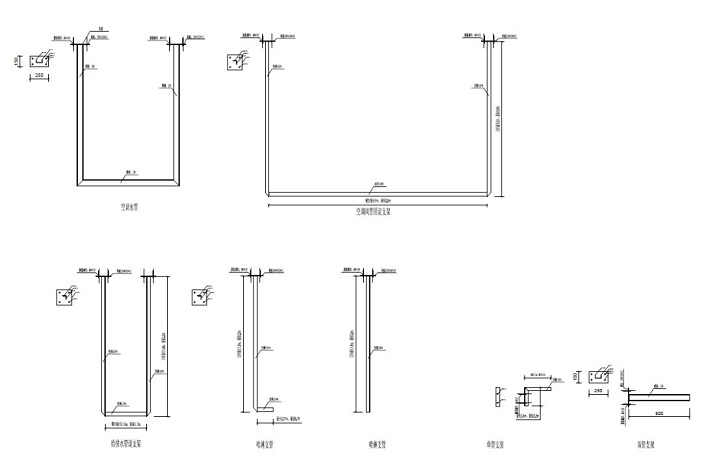

Anti-seismic brackets are mainly used in

the construction industry. At present, the main production mode is manual

welding. Therefore, there are some disadvantages, such as low feeding

efficiency, poor operating conditions of personnel, uncontrollable product

quality, etc., and there is no batch production capacity to undertake large

orders.

In order to change these constraints, it is

an inevitable trend for the development and breakthrough of the industry to

adopt welding robots with high quality, high efficiency and low maintenance

cost.

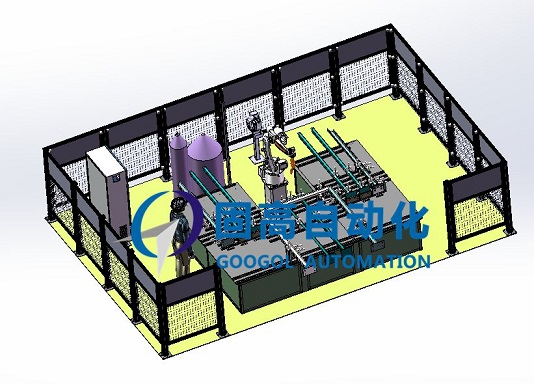

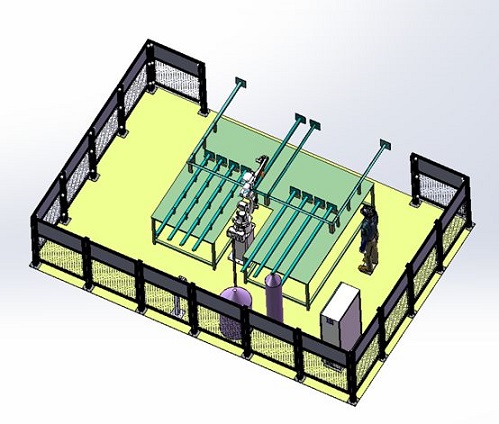

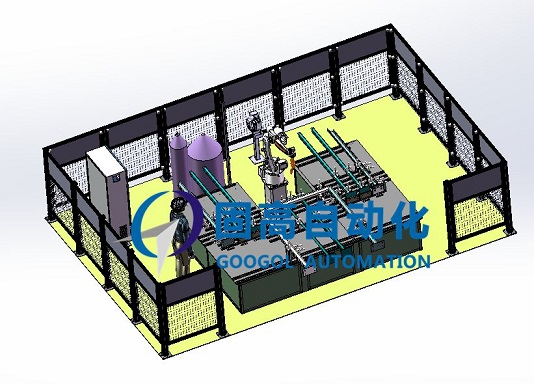

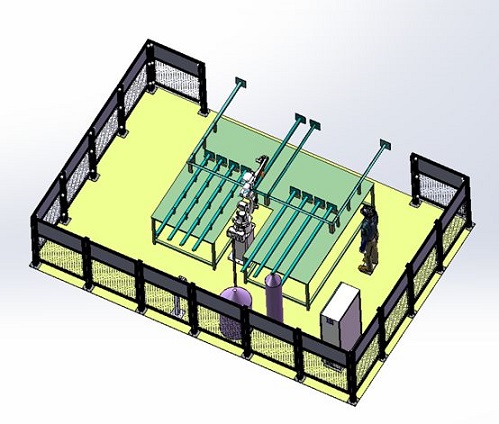

Googoltech’s Robot works hand in hand with

Guiyang Project Department of the Third Bureau of China Construction to help it

realize automatic welding of products. This welding robot system has high working

efficiency, which is at least three times higher than the efficiency of manual

production. It also changes the previous three-shift production mode, greatly

reduces the labor intensity of workers, and improves the product quality. It

has enhanced market competitiveness.

Workstation Features:

1. By using solid-high-middle hollow arc

welding robot, more welds in azimuth can be welded and the welding efficiency

of the workpiece can be improved.

2. Robot torches are equipped with

anti-collision sensors, which can protect the torches and robots to the

greatest extent even if improper use of collision guns.

3. flexible tooling (adjustable),

compatible with more products. The tooling can realize quick clamping and

positioning to prevent the workpiece from being forced and deformed.

4. In the process of welding robot

operation, the workpiece can be loaded or discharged manually by using double

welding positions, and the efficiency of welding robot is applied to the

greatest extent.