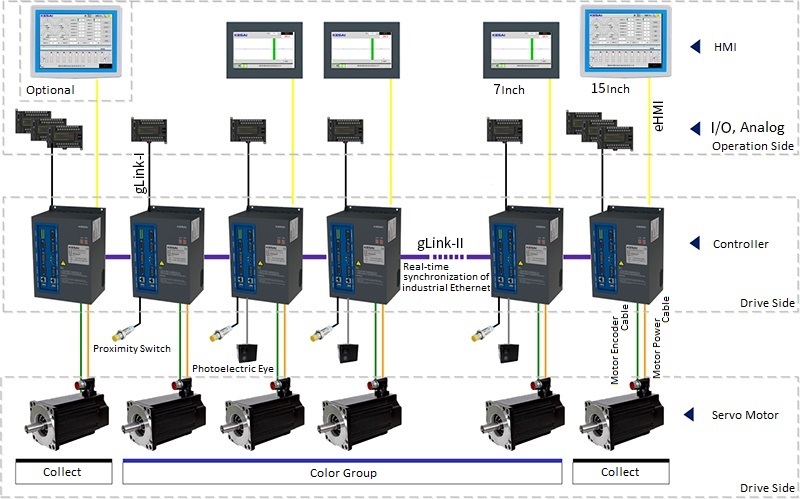

The project breaks through the bottleneck of the traditional electronic shaft gravure separation control system, integrates the motion control system, the color control system and the tension system, reducing the physical connection and simplifying the on-site installation and maintenance of the equipment. The system is based on Googoltech's gLink-II (Real-time synchronization of industrial Ethernet) communication protocol, and using the ring topology. It can realize data redundancy and link redundancy, ensure high-speed real-time response and big data transmission of the system, and improve communication reliability of the system. The system can also be connected to the customer's color-coded sensor to improve the recognition and accuracy of color detection. This project is designed for gravure printing machine, with stable performance, reliability and compact structure.

● The system sets the isocyclic network communication to 250us;

● The system network is synchronized with a distributed clock, and the synchronization jitter is less than 1us;

● The refresh period of IO is 250us;

● The response bandwidth of position loop is 50Hz, the response of speed loop is 300Hz, and the response of current loop is 1KHz;

● The system can configure 128 color groups, each of which can be attached to 64 extended IO modules;

● Integrated virtual code disk output function, which can easily connect to the still picture system and other external devices that require an encoder;

● Increase the CAN communication interface, which can be easily connected to the simple operation box to reduce the cost;

● Supports Sin-Cos encoder, pulse encoder and absolute encoder feedback type, which provides greater flexibility for servo motor selection;

● Additional external encoder input can easily track the existing variable frequency motor work, such as cross cutting, die cutting, hot stamping, indentation and other functions.

System Advantage

● Compact structure: Integrated motion control system, color control system and tension system, reducing physical connection and simplifying on-site installation and maintenance of equipment.

● Reliable performance: The system is based on Googoltech's gLink-II (Real-time synchronization of industrial Ethernet) communication protocol, which uses a ring topology to achieve data redundancy and link redundancy.

● Convenient maintenance: centralized debugging, which can update the hardware, various parameters and application layer OtoStudio program on any site; Provide remote diagnosis and remote upgrade function, which can be easily connected to the internet for remote monitoring and maintenance upgrade.