The warp knitting machine is mainly composed of weaving mechanism, guide-bar shogging mechanism, let-off mechanism, drawing and winding mechanism and a transmission mechanism. The warp knitting machine with jacquard function needs to be equipped with a Jacquard device to achieve the jacquard needle selection.

Process Analysis of Warp Knitting Machine

1. Process requirements of guide-bar shogging device:

● Shogging movement according to the structure of the textile, the amount of shogged should be an integral multiple of the needle spacing;

● Shogging movement must be closely matched to the swing (spindle);

● When the guide needle swings to the needle plane, the guide-bar cannot be shogged, otherwise it will hit the needle;

● The guide-bar shogging movement meets the requirements of dynamics;

● At present, electronic cam control is used to replace the traditional chain block and mechanical cam. For this reason, an electronic shogging control system has appeared on the market.

2. Process requirements of let-off motion:

● In the weaving process, the control system should output the specified length yarn within the rows specified number according to the let-off quantity required by the process. The warp beam motor needs to change with the spindle angular displacement, and the outside length of the warp beam head to needs to determine the angular displacement of the warp beam motor (let-off quantity);

● At present, electronic gear control is used instead of the traditional mechanical method, and there is a separate electronic let-off control system on the market.

3. Process requirements of Jacquard control system:

● In the weaving process, the control system should accurately implement the left and right deviations of the corresponding needle position of the Jacquard needle block at the specified trigger angle according to the action required by the process.

Main Features

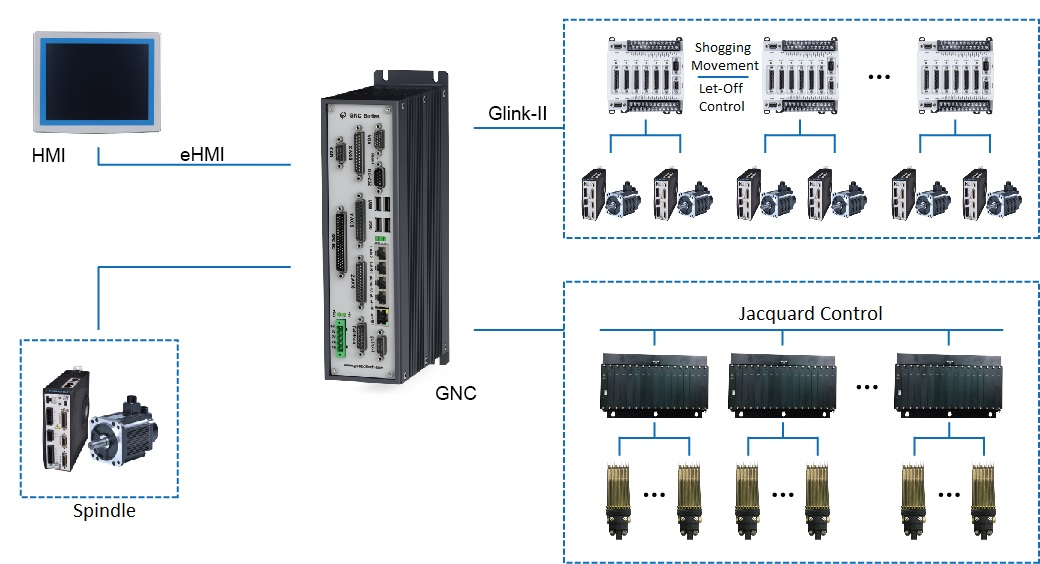

● The main control unit based on X86+DSP+FPGA architecture can control 25 motor shafts;

● The shaft has electronic gear and electronic cam function;

● Integrate electronically controlled functions such as let-off, shogging movement, Jacquard, and take-up;

● It can be realizing the control of 32pcs Jacquard control box (control 1024pcs Jacquard comb);

● With power-down data protection function, it can automatically weave continuously after power-on;

● Supports Ethernet connection, which can interconnect multiple devices to implement remote monitoring and information exchange.

● It has strong expandability and other interfaces such as CAN interface and RS232, which is convenient for extending other functions.

System Advantage

● With motion controllers, it has advantages in processing data and implementing complex control strategies. For the same configuration, the production efficiency is improved by more than 20% compared with other control schemes;

● Realize three-in-one of the let-off, shogging movement, Jacquard control, the software operation is simpler, and the system operation is more stable and reliable;

● Based on motion controller with a variety of error compensation schemes, it can compensate for mechanical deficiencies within a certain range and reduce the amount of debugging and assembly work;

● Integrated information management system, the production information of all connected machines can be transmitted to the cloud in real time. Through the analysis and processing of the data, the production manager can see the production situation, thus making the production scheduling more efficient.